New F-Gas regulation and leak detection

How does the latest F-Gas Regulation affect refrigerant leak detection?

January 2014 saw the revised EU Regulation of F-Gases following publication of a draft proposal by the European Commission at the end of 2012. The much anticipated regulation changes aim to strengthen the existing F-Gas Regulation and to ‘encourage’ the industry to move towards a HFC free market and use of low GWP (Global Warming Potential) refrigerants.

How can we reduce our F-Gas emissions?

There has been much discussion surrounding F-Gas emission reduction and the most practical methods in doing so. The two key methods we can implement are High GWP emissions reduction and to employ an effective leak detection programme.

– High GWP Emission Reduction

One theory is to use low or very low GWP refrigerants. The refrigeration industry is being ‘encouraged’ to move towards a HFC free market and use of low GWP refrigerants. For many people, this is an ideal solution as many of these refrigerants have a GWP score of less than 10, however there are constraints withusing these gases, with flammability being one.

– An Effective Leak Detection Programme

Refrigerant gas leakage to the atmosphere can result in product loss, causing systems to operate inefficiently and is detrimental to the environment, therefore breaching F-Gas Regulations. The F-Gas Regulations now have a greater emphasis on gas leak detection therefore it is important to understand how the new GWP concept affects leak detection.

What is the GWP concept?

The EU has now agreed to ban the use of HFC’s in new equipment in a number of sectors, most notably in commercial refrigeration by 2022. In addition, from 2020 very high GWP HFC’s above 2500 will no longer be used to service and maintain refrigeration equipment.

The intention is to put all greenhouse gases onto a common scale and GWP, however imperfect, remains the recommended metric to compare future climate impacts of emissions of long-lived gases. Under the new proposal, sites now have to factor in the GWP and make a calculation relative to CO2 equivalent emissions. Recent discussions have highlighted the issues concerned with identifying the correct GWP used to calculate the requirement for leak detection. A simple look through the search engines for the likes of R404a throws up a number of GWP scores making it difficult to determine an accurate calculation.

A simple framework with set GWP figures needs to be made available for the refrigeration industry. This will undoubtedly complicate things for many site operators who will be asking ‘how do we calculate how frequently we need to check for leaks’? And ‘we didn’t need to have fixed leak detection under the existing regulations; do we need it under the new F-Gas regulation’?

So how does this affect refrigerant leak detection?

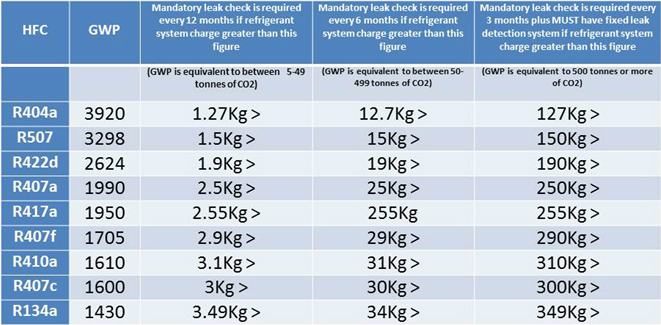

Under the former F-Gas revision, customers simply had to know what Kg charge they had to dictate what leak detection frequencies/requirements applied, but they now have to factor in the GWP and make a calculation relative to CO2 equivalent emissions (or use our table).

The table allows anyone using the most common refrigerant charges to evaluate frequency of leak checks plus if there is a requirement for fixed leak detection equipment.

Simply find your HFC and see which bracket your refrigerant system charge falls into.

As you’ll see, it’s clear were the agenda lies in terms of measures to reduce high GWP refrigerants. Generally speaking, the limits are worth noting for most HFC’s. For those with R404a who have a refrigerant system charge up to 300kgs under the previous regulation, they will now require a fixed leak detection system for a charge over 127Kgs.

The new F-Gas Regulation will be implemented in January 2015 so you need to start reviewing your requirements now to ensure you are compliant with leak checking procedures, there is though a two year transitional period to allow the switch over from KG to CO2 equivalent, the CO2 requirement will be for new equipment being placed onto the market, so existing systems can stay with the old KG labeling but the C02 rating will apply to the need for leak testing.